Land Development Services Alert:

In our continuing effort to ensure submitters have the tools necessary for successful record plat submissions, Land Development Services (LDS) has updated the Simple Subdivision Eligibility Checklist.

In our continuing effort to ensure submitters have the tools necessary for successful record plat submissions, Land Development Services (LDS) has updated the Simple Subdivision Eligibility Checklist.

The updates include the following:

All LDS forms can be found on the Forms & Publications Library page.

The updated checklists must be included with all Simple Subdivision Record Plat submissions along with the Record Plat Checklist for Simple Subdivisions after March 15, 2022. Either the current or the updated checklists can be used until March 14, 2022.

If you have questions about the above checklists, please reach out to Kati Barczay in the Site Development and Inspections Division (SDID) by email or 703-324-1720, TTY 711.

Recent changes to the Virginia Stormwater Management Program (VSMP) Regulations § 9VAC25-870-65.D.1. impact the use of certain proprietary Best Management Practices (BMPs).

The Virginia Department of Environmental Quality (DEQ) issued new technical guidance on Sept. 15, 2021, regarding proprietary BMPs. The new guidance requires manufacturers of proprietary stormwater BMPs to provide documentation to DEQ if their BMP was listed on the BMP Clearinghouse website prior to July 1, 2020. The documentation must show that another state, regional or national certification program has verified and certified its nutrient or sediment removal effectiveness to continue to be approved by DEQ. DEQ has updated the list on the Virginia Stormwater BMP Clearinghouse to show which BMPs meet or do not meet the new requirement.

To ensure compliance with DEQ guidance, Land Development Services will process stormwater management plans submitted as part of any site, subdivision or grading plan as follows:

The list of Manufactured Treatment Devices Approved for Use in Fairfax County has been updated to clarify those proprietary BMPs that meet the new requirement and have been approved by the Land Development Services Director for use in Fairfax County in accordance with Public Facilities Manual § 6-0402.3B. If you have questions, please email Department of Land Development Services, Site Development and Inspections Division or call 703-324-1720, TTY 711.

For additional guidance, see the DEQ’s Technical Guidance Memo No. GM21-2006.

A pilot project on Arley Street in Springfield is an environmental success story. With significant community initiative and modest government assistance, 4,300 square feet of asphalt in the Springfield district was converted back to green space.

Community property within the Springfield Station Homeowners Association (HOA) included a deteriorated basketball court which was at the end of its lifecycle and no longer provided a useful benefit to the community. During planning for the community space, residents decided to remove the basketball court entirely. The HOA applied to the Northern Virginia Soil and Water Conservation District’s (NVSWCD) Conservation Assistance Program (CAP) for cost-share funding and technical assistance for the proposed conversion of the basketball court to green, open space. The community space is entirely within the Resource Protection Area (RPA) of an unnamed tributary of Middle Run (Pohick Creek) and eventually flows into the Potomac River. The community planned to remove the asphalt surface and reduce the compaction of the soil by adding at least two inches of topsoil and compost. With this plan in mind, NVSWCD confirmed that the project was eligible for participation in CAP because it promotes infiltration, reduces the potential for nearby flooding, and improves stream health.

Through a newly established partnership between NVSWCD and Fairfax County’s Land Development Services (LDS), the project was able to receive the maximum possible cost-share amount eligible under the CAP. This partnership effectively created the new NVSWCD/LDS Water Quality Improvement Program (WQIP), whereby LDS allocates funding for eligible CAP projects with funds collected under LDS enforcement action, thus improving the environment within the impacted communities where violations previously occurred. The Springfield Station HOA project was the first recipient of funding from the newly launched partnership.

The public-private partnership is one that will be replicated throughout the county for other community association and places of worship projects approved under the CAP program. Thus the 4,300 square feet could represent the first step in projects that occur across the county, improving water quality in every district.

LDS project lead Brandy Mueller said, “Though small in terms of scale, this project was really a huge endeavor and a great benefit to the community. This new partnership seeks engagement and environmental opportunities. We hope this successful case study will encourage others to pursue similar projects.”

Replacing impervious asphalt (which does not allow water to pass through it) with green space results in multiple environmental benefits:

Learn more about the Conservation Assistance Program.

Fairfax County will launch the third phase (Release 3) of the new Planning and Land Use System (PLUS) in January 2022.

PLUS will serve as Fairfax County’s central platform for customers to complete zoning, building, permitting and other land development processes.

Multiple transactions have already moved to the new PLUS platform. To see transactions already accessible via PLUS, visit the PLUS Support Center.

Release 3 will add the following transactions into the PLUS platform:

As we release PLUS functionality, our existing systems may be down for a day or more. As more details are confirmed we will update the PLUS Support Center webpage.

![]()

The Department of Land Development Services (LDS) has launched a Green Building Recognition Program to acknowledge designers and contractors who voluntarily build green in Fairfax County. The new program supports Fairfax County’s environmental vision and recently adopted Green Initiatives. The program highlights the design, construction and operation of new construction that reduces environmental impact to our community.

The self-reporting program is geared towards new residential and commercial development. Projects are identified during the permitting process by the submitting designer/builder selecting the appropriate green building criteria found on the updated Building Plan Review Coversheet.

Qualifying criteria includes the following:

The name of the identified designer, builder, Magisterial District, and project name (if applicable) will be published on LDS’ new Building Green webpage once the associated building permit is issued. The owner/developer’s name will only be reported upon request.

We further encourage designers and builders to share a photo of the completed project for inclusion on the webpage by forwarding to our web team and including the building permit number.

If you have any questions, please contact the Building Review team at 703-222-0801, option 2, then option 3, TTY 711 or by email at LandDevelopmentServices@fairfaxcounty.gov. Learn more about Fairfax County Green Business programs.

By Krishna Loomba

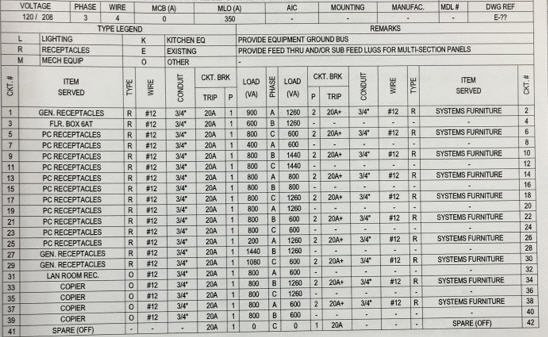

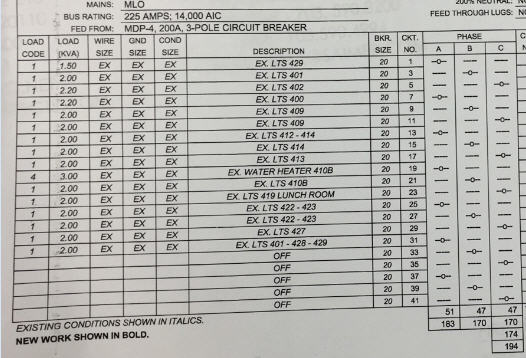

A simple issue plagues many electrical plans that can be easily remedied and potentially prevent a plan review rejection. Circuit directories, required on the electrical plans and in the field on switchboards and panelboards, are often incomplete, vague and lack specific detail. Article 408.4(A) of the 2017 National Electrical Code requires circuits to be legibly identified on a circuit directory located inside or on the face of the panel door for their intended purpose or use. Sufficient detail must be provided to allow each circuit to be distinguished from others. For instance, as seen in Figure 1 below, odd numbered circuits five through 25 are only identified as “PC RECEPTICLES.” Missing are room numbers or other location identifiers. See Figure 2 for an example of a directory with sufficient description on location.

Fairfax County’s Public Facilities Manual (PFM) has transitioned to a new platform to provide an enhanced user experience: https://online.encodeplus.com/regs/fairfaxcounty-va-pfm/index.aspx.

The new location and layout of the PFM provides a more user-friendly approach to the PFM with enhanced search capabilities and links to outside web pages and documents as well as direct links to PFM tables and plates.

From the Land Development Services web page, you can still access the PFM, and PFM amendments, from two locations:

Please make any adjustments needed and update bookmarks to the PFM you have previously saved. We hope you like the new layout for accessing design details and site development guidelines for public facilities in Fairfax County.

When the coronavirus pandemic reached Northern Virginia, county facilities were insufficient to meet the ongoing and future demands of a virus for a county with a population of more than 1,100,000 spread across 406 square miles. Staff at the Fairfax County Health Department knew a quick, reliable community-wide testing strategy would be critical. Attempting to “box in the virus” to prevent its spread would require more resources. Health Department staffing, equipment and space would need to be augmented – at least for the duration of COVID.

When the coronavirus pandemic reached Northern Virginia, county facilities were insufficient to meet the ongoing and future demands of a virus for a county with a population of more than 1,100,000 spread across 406 square miles. Staff at the Fairfax County Health Department knew a quick, reliable community-wide testing strategy would be critical. Attempting to “box in the virus” to prevent its spread would require more resources. Health Department staffing, equipment and space would need to be augmented – at least for the duration of COVID.

In March 2020 Health Department capacity was limited to testing 500 COVID samples daily using approved diagnostic testing methods. But staff projections showed a need to test twice that amount, or 1,000 samples per day, going into the fall 2020.

Thanks to federal CARE funding distributed by the Virginia Health Department the county had the funding to expand its resources. Health Department human resources staff put together plans to recruit and train new staff, and the Health Department Lab Director Deb Severson met with the county’s Capital Facilities staff (a division of the Department of Public Works and Environmental Services, DPWES) to put together criteria for a new medical laboratory (Lab). Every lab requires standard microbiological practices but testing for coronavirus required a Biosafety Laboratory Level 2 (BSL–2). This level of biosafety required certain specifications such as ensuring the flooring, walls and ceiling would be impermeable and seamless, have self-closing, lockable doors, have a sink and eyewash station, a dedicated supply/exhaust, 100% air exchange every 12 minutes; passthrough autoclave; self-closing doors; HEPA Air filtration, ducted air ventilation system that must sustain directional air flow, and the ability to restrict entry among other safety specifications for benchtops, cabinetry and other add ins. The new building would be 1,550 square feet and have an accessioning laboratory, restroom, administrative office and exam room.

The need was urgent, but normally locating an appropriate site or building, putting contracts together and retrofitting or renovating a space takes many months, even years, including applying for and obtaining appropriate permits. In this case, time was of the essence and the county had less than six months to spend the funding from the state.

After consultation with various county departments, including Land Development Services (LDS), it was determined a prefabricated structure could meet the requirements for a BSL-2 lab, meet additional building codes and would be the most economical and time-efficient structure to use. This would be the first structure of this kind – cargo containers – used in Fairfax County. Once the requirements were documented, the Department of Procurement and Material Management sent out a request for proposal in August.

Synergy Med Global Design Solutions, LLC, (Synergy Med) won the competitive bid to be the supplier of the new lab. (Watch a Synergy Med video about the project.)

County staff from LDS and DPWES worked closely with the designers – architects and electrical, plumbing and mechanical engineers at Synergy Med -- from the first meeting on November 13, 2020, through issuance of the building permit on December 8. The deadline for installation was December 30 due to the funding restrictions. Scott Bishop, a project manager for Building Design & Construction Division in DPWES, oversaw the entire project from start to finish including all the on-site work in Fairfax County, and Jennifer Josiah, of LDS, was the project manager, coordinating with divisions within LDS, the Department of Planning and Development, the Fire Marshal’s office and Wastewater Planning (also in DPWES) for plan review, permit issuance and inspections. It took countless virtual meetings, emails and phone calls with people across the U.S., Colorado, Minnesota and Hawaii to finalize the details and make sure every aspect of the structure was completed according to code.

Modular facilities follow a separate section of building codes than typical commercial structures such as restaurants, retail stores and office buildings. The prefabricated (or “prefab”) building Synergy Med constructed for the county started with cargo containers. But, because the containers were going to be modified and the exterior would be pierced, they had to be reviewed under the 2015 Virginia Construction Code, just like any other commercial building. This type of building is often used by the U.S. military overseas to help triage medical patients in the field.

Synergy Med built the structure in Minnesota where they are located. Inspectors from Land Development Services in Fairfax County were able to see the building being put together remotely using FaceTime and other virtual tools including a 3d video. This was important as some of the components county inspectors needed to see would be concealed behind walls before the building was delivered to Fairfax County.

The Lab consisted of five cargo containers, so inspections had to occur on each container. The containers were transported individually and then locked together on site in Fairfax County.

The Lab consisted of five cargo containers, so inspections had to occur on each container. The containers were transported individually and then locked together on site in Fairfax County.

The Lab was loaded onto trucks in Minnesota on December 23 and arrived in Fairfax County on December 28.

After delivery, the Lab was placed on concrete piers using bolts and put together like a puzzle. Once it was deemed structurally sound and safe to enter, it was wired for the Health Department’s DIT specifications and the furniture was placed while utilities were connected, and final inspections were performed. The Non-Residential Use Permit (Non-RUP) and Certificate of Occupancy were issued for the facility on January 25, 2021, and the Health Department moved in shortly thereafter.

“This project was the result of an incredibly collaborative effort on the part of multiple agencies throughout the county. Everyone understood the urgency of the need and worked to get the lab in place as quickly and safely as possible, meeting the tight deadline for the necessary funding,” said Project Manager Jennifer Josiah.

So, a project that could take more than a year to complete was operational in under 100 days. The team met the December 30, 2020, deadline for making the Lab fully functional, and occupancy was certified by January 25, 2021. The final cost of the facility was $4,000,000.

Fairfax County has expanded by one facility, temporary maybe, but fully operational, certified safe by staff at Land Development Services and meets the state-of-the-art standards for sanitization and medical testing.

More photos of the health Lab in this slideshow.

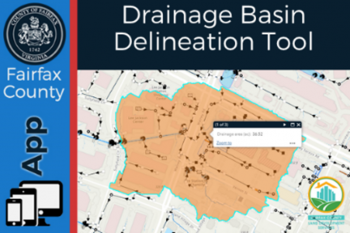

Drainage basins, or watersheds, are areas of land that drain streams and rainfall to a common outlet. This new interactive Geographic Information System (GIS) tool allows users to drop a point on a map and delineate the drainage basin anywhere in the county.

Drainage basins, or watersheds, are areas of land that drain streams and rainfall to a common outlet. This new interactive Geographic Information System (GIS) tool allows users to drop a point on a map and delineate the drainage basin anywhere in the county.

This is valuable data used by engineers to ensure the county’s stormwater management infrastructure is adequately sized. The data is also used by ecologists when evaluating relationships between land use and hydrology, their influence on stream condition, water quality and aquatic life.

To find the drainage basin nearest you, check out the newest GIS app: Drainage Basin Delineation Tool, which uses LiDAR data (the most accurate elevation surface available), to delineate drainage basins. To learn more about watersheds, visit Watersheds | Public Works and Environmental Services.

To find the drainage basin nearest you, check out the newest GIS app: Drainage Basin Delineation Tool, which uses LiDAR data (the most accurate elevation surface available), to delineate drainage basins. To learn more about watersheds, visit Watersheds | Public Works and Environmental Services.

This is only one of many GIS applications developed by Land Development Services (LDS). To explore more LDS GIS applications please visit our LDS Mapping Applications homepage.

By Anurag Baral

(original publish date: Aug. 17, 2017)

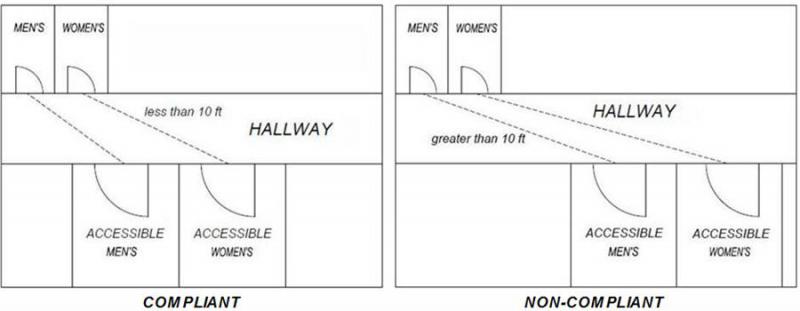

If you read Section 1109.2 of the 2018 Virginia Construction Code (VCC), you are provided with location requirements for accessible restrooms. If you pay particular attention to Exception 3, you will note that while it specifies how many restrooms are to be in a cluster, it does not define the term cluster.

1109.2 Toilet and bathing facilities.

Each toilet room and bathing room shall be accessible. Where a floor level is not required to be connected by an accessible route, the only toilet rooms or bathing rooms provided within the facility shall not be located on the inaccessible floor. Except as provided for in sections 1109.2.2 through 1109.2.4, at least one of each type of fixture, element, control or dispenser in each accessible toilet room and bathing room shall be accessible.

Exceptions:

The Building Division will consider clustered toilet and bathing rooms as two or more single-occupant toilet rooms or bathing rooms, with entrance doors plainly visible from one and other, located either adjacent to each other or across the hall from each other and having a maximum travel distance of 10 feet measured from center of door to center of door of the nearest toilet/bathing room (see figures above). Please note that signage requirements of VCC Section 1111.2 still apply.

For more information, please contact Billy Farmer at 703-324-8361, TTY 711 or via email.